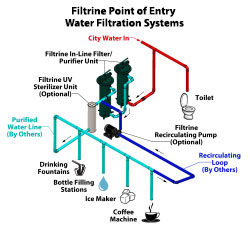

Point of Entry Purification Designed for City Water Entering Buildings

Lead, pathogens, chlorine, organic odors and particles down to 0.5 microns are removed and the purified water is dispensed to coffee makers, sinks, drinking fountains, bottle filling stations, toilets and more. The elements sit inside heavy-duty stainless steel housings that are rated at 150 psi working pressure.

Stage One: The point of entry two-stage process starts with pre-filtration using Filtrine’s Particulate Spun-Poly Filter. Particulate matter is removed, clarifying the water. (In the optional three-stage process, the filter cartridge also eliminates particulate shadowing in the UV sterilization chamber increasing the destruction rate of water borne pathogens.)

Stage Two: Next, Filtrine’s popular biodegradable Lead Miser Purifier improves water quality and the sterilization process by using activated 0.5 micron carbon block elements that meet the NSF/ANSI Standard 42 for removal of sediment, organic tastes/odors, and chlorine taste/odors. It also removes lead and pathogens including Cryptosporidium, Entamoeba Giardia and Toxoplasma to meet NSF/ANSI Standard 53.

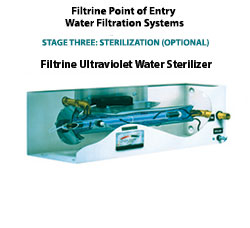

Stage Three: The optional stage three Ultraviolet (UV) Water Sterilizer eliminates micro-organisms which can cause water borne diseases. No chemicals or toxic products are used and operation is low cost because the energy consumption is equal to ordinary fluorescent tubes. Standard plumbing connections and grounded electrical outlet make for an easy installation. The quartz sleeve and UV tubes can be cleaned or replaced in minutes for quick maintenance.

Filtrine Service Contracts Are Recommended

Filtrine service contracts cover labor and materials to monitor and maintain the operation of the filtration module. It includes the changing of filter elements on a scheduled basis no more than three times per year. For more information, contact the factory.