A modular medical building manufacturer based in Florida, RAD Technology Medical Systems, contacted Filtrine to see if they could manufacture a custom chiller that would cool cancer treatment equipment consistently along with the air conditioning unit and yet be durable enough to be moved in their Patented TRV Building System to the next hospital without loss of efficacy.

RAD Technology Medical Systems leases and sells modular vault and clinical buildings that can be installed in days or weeks to provide temporary clinical services while a health facility replaces its equipment. They may be in service for only a few months before they are disassembled and moved to another location. The up to 14 feet thick walls of the modular vault are filled with granular shielding material that can be removed with industrial vacuums when the building needs to be disassembled.

Filtrine’s specialty is to design custom chillers to cool all types of medical and industrial processes. So when presented with RAD Technology’s unusual medical cooling requirement, Filtrine stepped up to the plate and built a specialized chiller, Model PCP-2500-270A-WP-MOD-QCP-1-AS, to cool cancer treatment equipment housed in a portable modular building that sits next to a hospital or treatment center.

Being completely self-contained, the relocatable building needed chilled water at 68°F (20°C) for the linear accelerator and 41°F (5°C) for air conditioning. The chiller also needed to fit into a small space in the corner of the modular building. Filtrine’s solution was to build two chillers into one rugged cabinet that could withstand the rigors of mobile transport and be easily serviceable from two sides. The 7-1/2 HP chiller supplied water to the linear accelerator and the 15 HP chiller is used for the A/C water.

The first stop for the newly built modular building ironically turned out to be Cheshire Medical Center in Keene, NH, Filtrine’s hometown. The hospital completed the upgrade of its new radiation equipment (including installation of a Filtrine PCP-750G-96AR-SSD medical chiller to cool their Varian linear accelerator used for cancer treatment) in 2013 and the temporary mobile building was disassembled for transport to another location. The RAD Technology Patented TRV Building System (along with the specially designed Filtrine chiller) was then moved to two other sites around the country within the same calendar year (Vail Valley, CO and Idaho Falls, ID). The following year, the TRV was moved to its fourth location in Reno, NV.

The building and the chiller are designed to work in high and low ambient temperatures from as far north as Maine and as far south as Texas. See medical chillers for more information. Fill out the General Inquiry Form for access to Filtrine’s medical chiller engineering bulletins.

If you are interested in a customized medical chiller for your application, fill out the Medical Chiller Request a Quote form or contact your local Filtrine chiller representative.

The photo (Courtesy of RAD Technology Medical Systems) shows the Filtrine PCP-750G-96AR-SSD medical chiller in the wire enclosure in the right corner of the RAD building in Reno.

Featured Filtrine Product

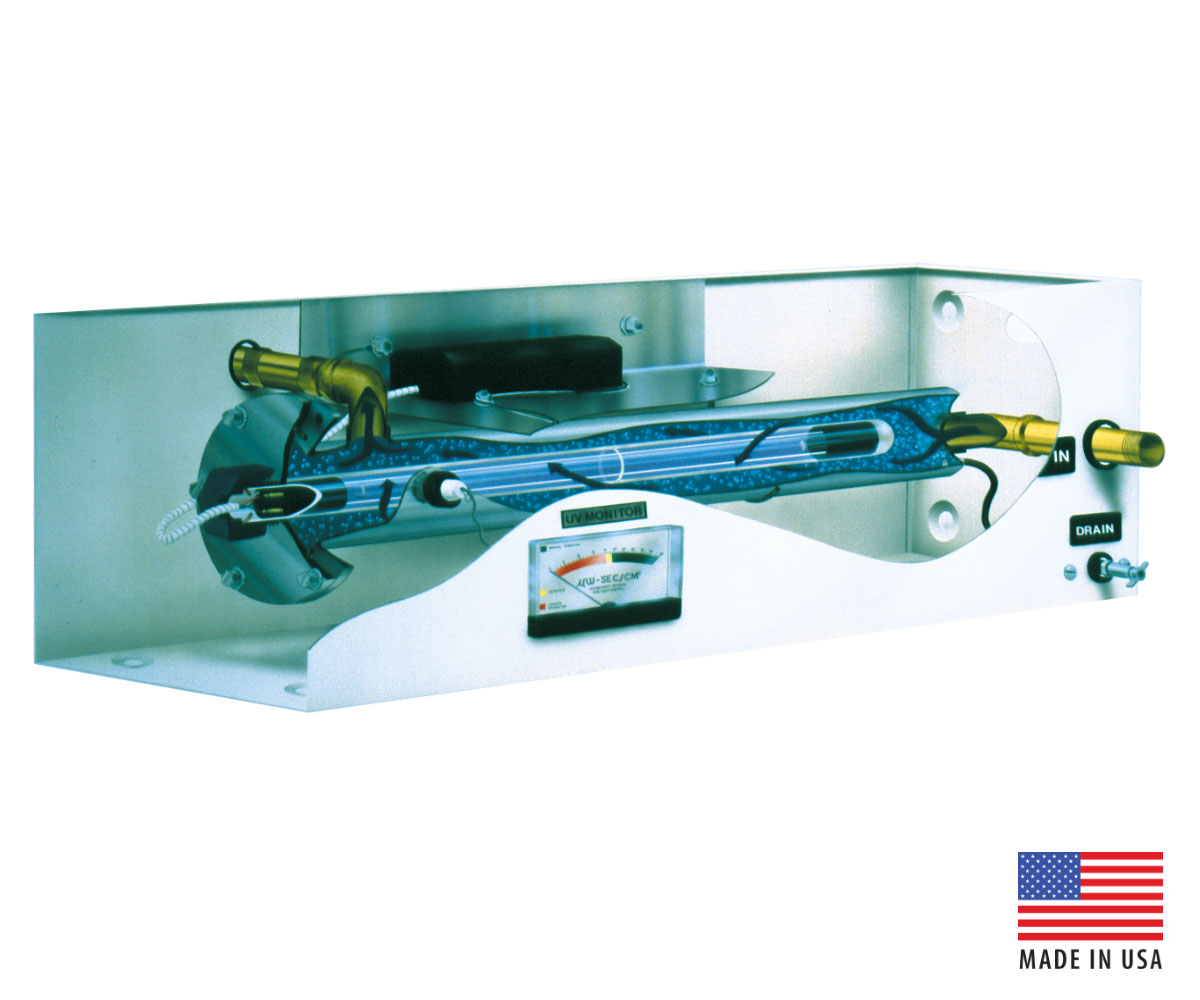

In Filtrine’s ultraviolet sterilizers, called the Steri-Flo series, the UV radiation with a wave length of 2,536 angstrom, is produced from a low pressure mercury lamp. The lamp is encased in a special high-purity quartz sleeve, immersed in water inside of the stainless steel sterilizing chamber. By regulating the flow of water through this chamber, disease-causing micro-organisms, such as bacteria, algae, spores and viruses are exposed to a dose of at least 40,000µw-sec/cm2, over twice the dosage required to ensure safe ingredient water. For more information, visit Water Purification.

For more information on any of these models, contact your local Filtrine Chiller Representative today.

Don’t miss the latest “Chiller Solutions Update”. Subscribe today!